Optimizing Manufacturing Flows in Manufacturing Facilities

In the current competitive landscape, optimizing manufacturing flows in production facilities is essential for ensuring efficiency and improving profitability. With progress in technology, industries are turning to innovative cutting solutions such as laser and water jet cutting services to streamline processes and enhance product quality. These methods not only provide precise cuts but also substantially reduce waste and downtime, allowing companies to meet increasing demands without sacrificing on standards.

As producers strive to achieve operational excellence, understanding the unique benefits and applications of diverse cutting techniques becomes essential. Laser cutting delivers high-speed precision, making it ideal for detailed designs and delicate materials, while waterjet cutting is celebrated for its flexibility and ability to handle dense materials without heat distortion. By integrating these cutting technologies into their production flows, facilities can maximize efficiency, reduce costs, and boost overall output, establishing the stage for sustainable growth in an ever-evolving market.

Guide to Laser & Waterjet Cutting

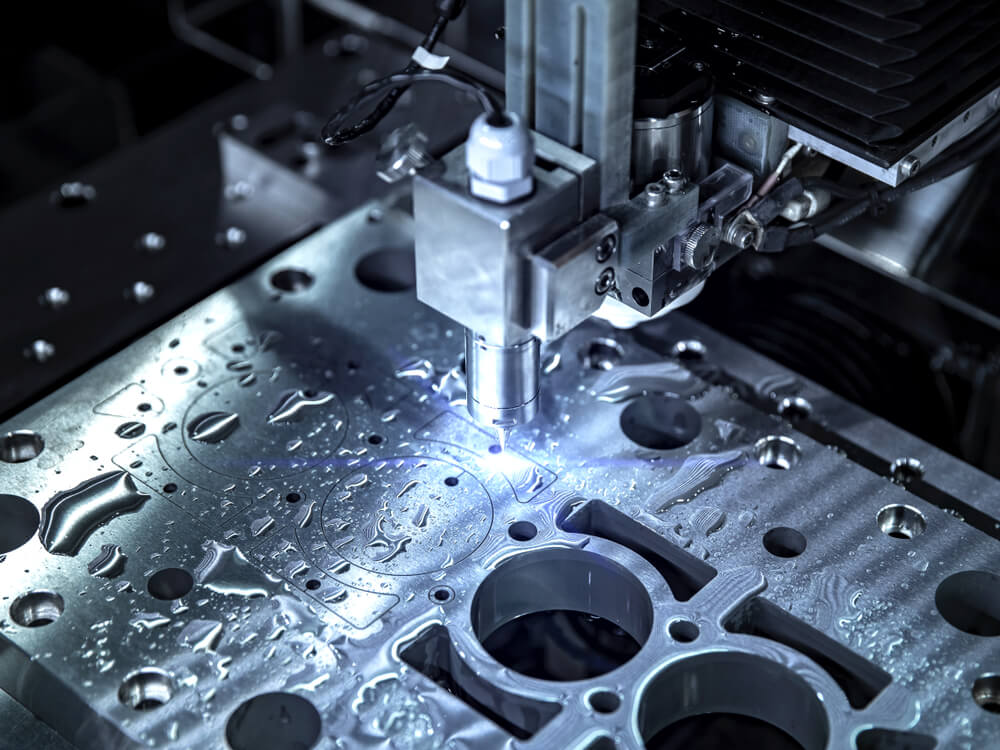

Laser and waterjet cutting services have revolutionized the manufacturing industry by offering efficient and precise methods for forming materials. Laser cutting uses focused light beams to melt, burn, or vaporize materials, which allows for extremely intricate designs and tight tolerances. It can be used on a wide range of substrates including metals, plastics and wood, making it a adaptable choice for various manufacturing needs.

Conversely, waterjet cutting, employs a high-pressure jet of water combined with abrasive particles to cut through materials. This method is particularly suitable for more substantial materials or those that are susceptible to high temperatures, as it does not lead to thermal distortion. Waterjet cutting can handle an variety of materials, including ceramics, glass and composites, making it a essential tool for industries that require a wide range of manufacturing prowess.

Both laser and waterjet cutting methods not only boost the quality of production but also optimize overall workflow in manufacturing environments. By incorporating these cutting services, manufacturers can boost their throughput, reduce waste, and enhance the accuracy of their products, ultimately leading to increased efficiency and competitiveness in the business landscape.

Benefits of Optimizing Production Flows

Improving operational flows within manufacturing facilities brings about substantial enhancements for productivity as well as performance. By simplifying operations, businesses can minimize time and resource consumption required to complete tasks. Such actions not just boosts overall output and also minimizes waste, permitting businesses to better concentrate on maximizing their return on investment. An efficient production flow can markedly reduce lead times, allowing quicker reactions to market needs and trends.

In addition, this improved workflow is likely to enhance product quality. If production methods are designed to be tailored for smooth transitions and fewer interruptions, the risk of errors as well as defects is reduced. Such precision is extremely important for industrial cutting applications, such as laser as well as cutting with waterjets, for which precision is paramount. A streamlined process results in more reliable as well as reliable quality, which fosters greater customer satisfaction and repeat business.

Additionally, optimizing production flows may lead to staff morale as well as workplace safety. An efficient operation allows workers to concentrate on their tasks free from the hassle of dealing with chaotic processes. Efficient facilities lessen the likelihood of workplace accidents, since hazards associated with disorganized and chaotic environments are lessened. Such a work environment not only enhances productivity but also aids in keeping skilled employees, leading to a more secure and experienced workforce.

Case Studies and Effective Strategies

In the past few years, a premier aerospace manufacturer adopted a combined approach utilizing both laser and waterjet cutting service s to enhance its production efficiency. The facility incorporated laser cutting for lightweight materials, which provided superior accuracy and speed, while waterjet cutting was employed for thicker, more resilient materials that required a alternative treatment. This strategic combination allowed the manufacturer to enhance its workflow significantly, cutting down on production time and waste while maintaining stringent quality standards.

Another pertinent example can be seen in the automotive industry, where a company adopted waterjet cutting for complex components needed for its vehicles. By leveraging this technology, they were able to reduce the thermal stress that often accompanies traditional cutting methods, thereby maintaining the integrity of the materials. Furthermore, this adjustment resulted in less frequent tool changes and a smoother production line, ultimately leading to enhanced output and lowered costs.

Lastly, a small-scale fabrication shop showcased the benefits of investing in both technologies by offering customized services to a diverse client base. By branding as a one-stop solution for both laser and waterjet cutting, they expanded their customer reach and satisfaction. This flexibility not only helped the shop stay competitive in a crowded market, but it also fostered innovation, as they could tackle special projects more efficiently with the appropriate tools at their disposal.